Technologies

Hubs

Because it would be illogical to present ourselves as true artisans by purchasing all our components from other brands, at Alian, we also design our own hubs.

To achieve this, we collaborate with the experienced German manufacturer Yuniper. Together, we imagine, design and produce unique, innovative and lightweight pieces in their Frankfurt workshop.

Our Alian hub by Yuniper® equips all our Diamant wheels.

Alian by Yuniper hub for disc wheels

Alian by Yuniper hub for skate wheel

The hub body is made of CNC aluminum alloy and anodized carbon.

All of our hubs are Straightpull compatible for high tension and better tensile strength. They are also very light, but not too much, because they should not deform.

We use Two/One technology on all our hubs to increase the number of tractor spokes on the rear wheels and thus obtain a perfect tension balance.

Our Alian by Yuniper hub uses a stainless steel cage annular bearing with ceramic internal surface treatment. Inside, the ceramic balls roll perfectly on the axle thanks to a special anti-friction grease.

All our hubs

To suit all practices and budgets, we offer a complete range of hubs.

The Spokes

Two/One Spoking and Tension Balance

The Two/One spoking on all our wheels is designed to achieve a perfect balance of tension.

The “Two” side reduces the flexing of the spokes in the entire wheelset. Thus, during cassette-side traction, its effect is greater than that of traditional spoking.

The DT Swiss Spoke

Aerolite

Chosen for its robustness and lightness, the DT Swiss Aerolite spoke shines with its lightweight and aerodynamic properties. It is the lightest flat spoke in the DT Swiss range and stands out for its high stability and excellent aerodynamic characteristics. Cold-forged to reduce the diameter to 1.5 mm, the central part is then flattened during a second forging process. This further increases the material’s strength and achieves the characteristic flat shape. This spoke fits into the standard spoke holes of the hub. It is mainly used on our front wheels and rear wheels for lighter riders and female cyclists.

Aero Comp

Aero Comp The DT Swiss Aero Comp spoke is chosen for the majority of rear wheels as it is stiffer and more resistant than the Aerolite. This spoke is first reinforced by cold-forging, making it lighter and stronger. During another sophisticated process, the spoke is flattened to optimize its aerodynamic properties and further increase material stability. The DT Aero Comp ensures a perfect balance between rigidity, aerodynamics, and stability. This spoke fits into the standard spoke holes of the hub.

The Diamant Carbon Rim

From design to final assembly,

a demanding and artisanal manufacturing process

Our Diamant rim is produced in Germany with carbon composite from Jura company Hexcel based in Slovenia and France.

To manufacture these wheels, we designed and produced our own molds in our partner’s workshop in Nuremberg. The rims are molded in this same workshop from 3k carbon fiber for the structure and UD for the finish.

We then obtain the perfect balance between resistance and lightness.

The spoke holes are made when laying the carbon layers. This process avoids drilling the rim afterwards. It reinforces the rim at the eyelets and solidifies the whole. Last asset, this process makes it possible to obtain wide possibilities of rigidity adjustments (flexible to very rigid).

Finally, we have innovated on the geometry of our rims to provide more comfort and grip in curves.

Step by step,

discover our manufacturing process

1. The mold

This mould, made to measure, integrates the holes of the spokes. When molding the carbon wheel, we thus obtain a much lighter and more resistant wheel.

2. Carbon fiber

We use carbon fibers from Jura company Hexcel in France and Slovenia.

3. The oven

To fuse together, all the carbon parts are heated in an oven at 120°C.

4. Stress testing

After cooling, we carry out numerous tests, including that of resistance.

5. Field tests

Final adjustments and final field tests before marketing.

6. The result

The photoshoot is over. Here is the end result. All you have to do is order.

Our other rims

Prestige Carbon Rim

Our Prestige rims (from Xiamen, China) are made from T1000 fiber, which is lighter and more tensile-resistant than T800, allowing for increased spoke tension.

However, in the same configuration, this fiber would be more fragile. Thus, the arrangement of the carbon fiber layers has been revised to solidify the rim.

Carbon rim Pro+ and Pro

Our Pro+ and Pro carbon rims (from Xiamen, China) are made from robust, lightweight T800 fiber and baked at 150°c for better resistance to braking temperatures. This fiber is covered with a UD finish fiber and a 45° Twill fiber on the braking strip.

On our Pro+ wheel model, we find a grooved brake band on which reduces the braking distance and thus saves rim wear and heating. The safety of the cyclist is therefore improved.

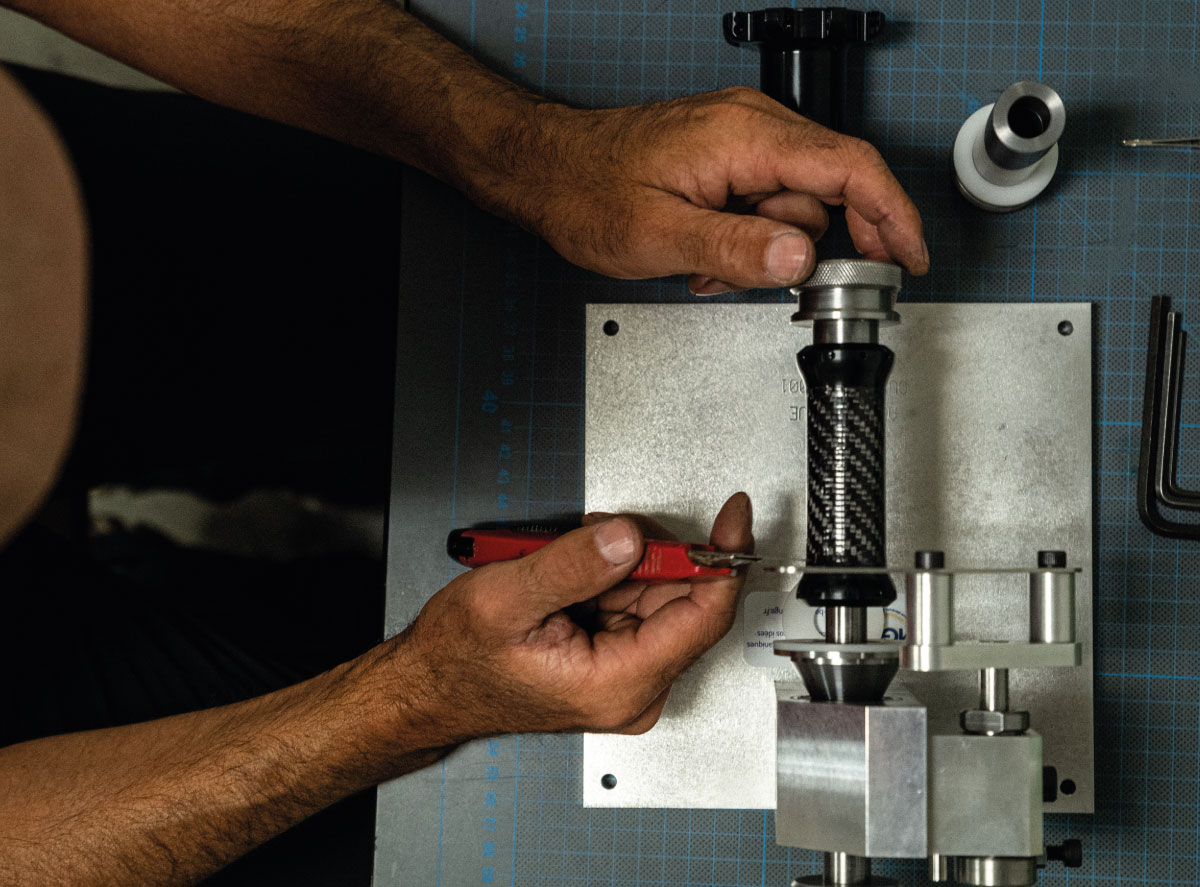

Precision is key

All our wheels are mounted using the Truing Stand of P&K Lie (Germany) and with a DT Swiss tensiometer in order to obtain precision to the 100th for the veil and the jump and to the Newton for the tension.

At Alian, we custom-fit each pair. Our precision tools are therefore essential to obtain the adjustment adapted to each customer (for example the tension of the Two/One shelving).

Finally, we push the requirement also in the choice of our suppliers. We choose suppliers whose materials and parts are the best, most durable and most reliable over time. We also weigh and check each part before assembly to ensure optimum quality.